Industry 4.0 in Île-de-France is redefining the regional industry through the integration of cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and additive manufacturing. This transformation proves to be a real opportunity for a region where innovation and strategic sectors such as aerospace, automotive, healthcare, and information technologies play a major role.

Companies in Île-de-France, both large and small, are embracing these technologies to enhance their performance, increase their competitiveness, and meet the challenges of an increasingly dynamic market. By automating their processes, leveraging real-time data, and optimizing resource use, they are able to reduce costs while boosting productivity. This evolution makes Industry 4.0 in Île-de-France a strategic driver for the region’s economic growth.

CIM Atlantique supports you in this transformation by offering innovative solutions tailored to your sector.

Key technologies for Industry 4.0 in Île-de-France.

Industry 4.0 in Île-de-France relies on the integration of advanced technologies, each playing a key role in transforming industrial processes. Here is an overview of the main technologies that define Industry 4.0.

Internet of Things (IoT)

Industry 4.0 in Île-de-France is distinguished by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and additive manufacturing. This transformation takes place in a dynamic region known for its innovations and particularly recognized for its leading sectors such as aerospace, automotive, healthcare, and digital technologies.

Companies in Île-de-France, both large and small, are embracing these technologies to gain productivity, flexibility, and to meet the challenges of an increasingly globalized market. Through process optimization via automation, real-time data analysis, and intelligent resource management, they manage to enhance their competitiveness while reducing production costs. Industry 4.0 in Île-de-France thus serves as a key lever for industrial modernization and regional economic development.

Artificial Intelligence and Machine Learning

Artificial Intelligence and Machine Learning

Industry 4.0 in Île-de-France stands as a crucial driver of innovation, with the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and additive manufacturing. This transformation offers a real competitive advantage for a strategically important region, particularly strong in sectors such as aerospace, chemistry, information technology, and finance.

Companies in Île-de-France, from large multinationals to innovative start-ups, are adopting these new technologies to automate their processes, analyze massive volumes of data in real-time, and optimize their resources. This not only helps reduce operational costs but also improves efficiency and responsiveness to the challenges of a constantly evolving global market. With this shift to Industry 4.0, the region positions itself as a key player in industrial innovation, capable of tackling future challenges while supporting the competitiveness of local industries on both the national and international stages.

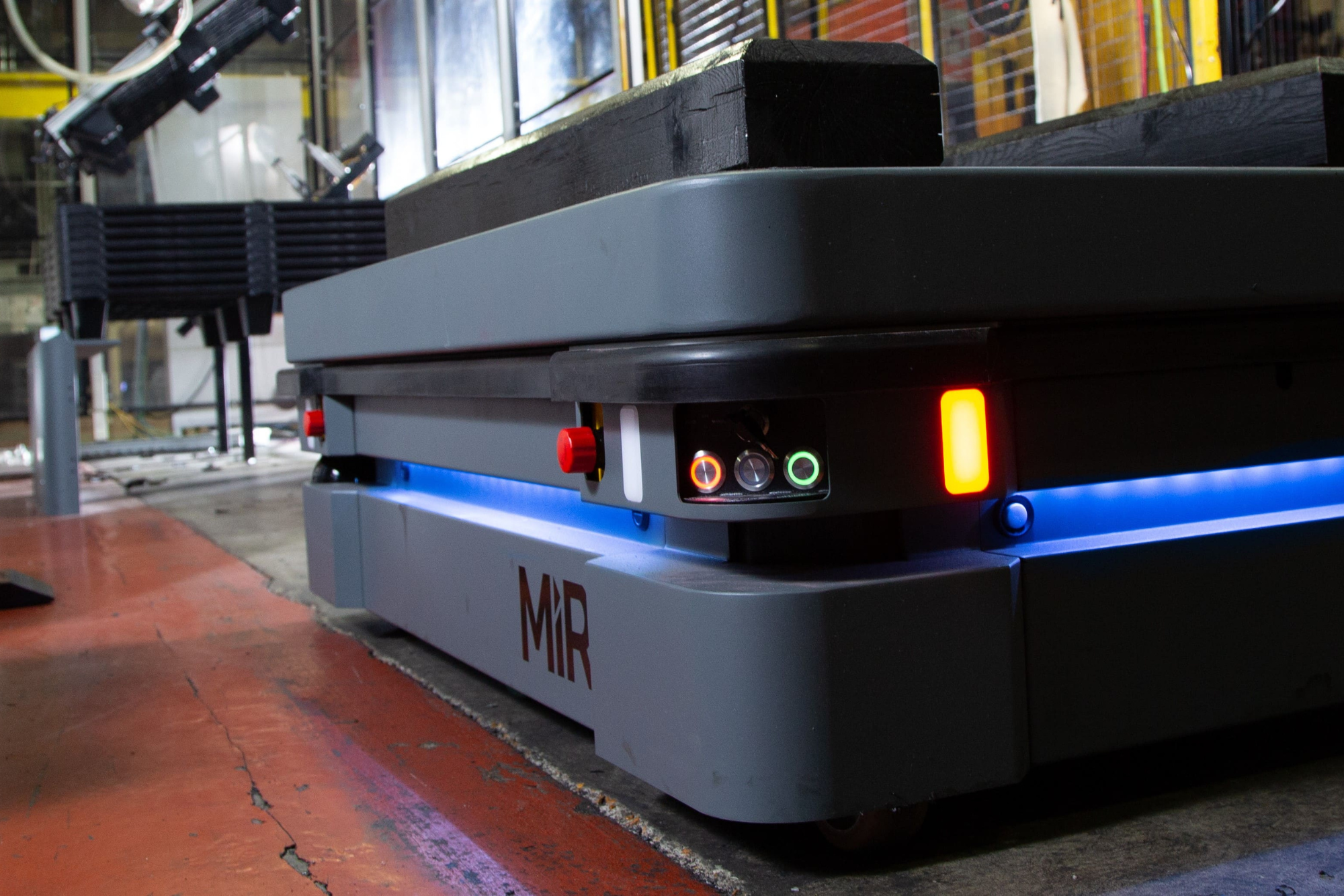

Advanced Robotics

Next-generation industrial robots play a crucial role in Île-de-France, thanks to the integration of advanced sensors and artificial intelligence (AI). These collaborative robots, or cobots, perform complex tasks with exceptional precision, assist human operators, and help increase their productivity without aiming to replace them.

In key sectors such as automotive and electronics, where demand is high and processes are often repetitive, these technologies enable optimized production while maintaining strict quality standards, which are essential for the competitiveness of businesses in the region.

Blockchain and Cybersecurity

Industry 4.0 in Île-de-France relies on the adoption of cutting-edge technologies, such as blockchain, which enhances the traceability and transparency of supply chains. In demanding sectors like pharmaceuticals and food production, this innovation serves as a strategic lever to ensure product compliance and secure the entire manufacturing process.

Given the increase in connected devices, cybersecurity has become a top priority in Île-de-France. The proliferation of smart objects increases the risk of cyberattacks, making it essential to adopt robust security protocols. These measures are crucial to protect sensitive data and ensure the stability of industrial operations in the region.

Additive Manufacturing (3D Printing)

In the Île-de-France region, additive manufacturing, or 3D printing, is reinventing traditional production methods by offering exceptional flexibility. Thanks to this technology, companies can design custom parts from digital models, precisely meeting their clients’ specific needs. By reducing waste and minimizing environmental impact, it supports more responsible production. At the same time, cost control and shorter manufacturing times provide key competitive advantages for businesses in the region, allowing them to stand out through their responsiveness and innovation capabilities.

Applications of Industry 4.0 in Île-de-France across different sectors

Industry 4.0 in Île-de-France has applications in numerous sectors, enabling a radical transformation of production and logistics.

Industry 4.0 in Île-de-France is revolutionizing the agri-food sector by integrating advanced technologies to improve supply chain management and production lines, while ensuring enhanced product safety. Through the implementation of IoT sensors, companies can monitor their processes in real-time, thus simplifying inventory management and production line control. Process automation allows for a significant reduction in costs while ensuring consistent quality at every stage of production. This model also promotes increased responsiveness to market demand fluctuations, providing businesses in Île-de-France with optimal flexibility.

The pharmaceutical sector in Île-de-France leverages advancements in automation to ensure that its manufacturing processes meet strict quality and safety standards. Thanks to Industry 4.0 in Île-de-France, the traceability of medications is enhanced, allowing for more precise risk management of contamination. Moreover, the integration of these technologies optimizes production, thus facilitating better adaptation to global requirements in terms of volume and compliance.

The automotive sector in Île-de-France is undergoing a major transformation thanks to Industry 4.0. The automation of production lines not only accelerates vehicle manufacturing but also ensures exceptional quality levels. Moreover, advanced technologies such as IoT and AI are integrated to optimize predictive maintenance of equipment and improve inventory management. The addition of 3D printing also opens up new possibilities by enabling the production of custom parts, which enhances flexibility and efficiency in production processes.

Why adopt Industry 4.0?

Industry 4.0 in Île-de-France is not just a simple technological evolution; it represents a true industrial revolution, supported by strategic investment in innovation. Thanks to region-specific support programs, companies can integrate cutting-edge technologies, thus strengthening their competitiveness in an ever-evolving global market.

The concepts of “factory of the future” and “smart factory” are at the heart of current discussions. These ideas illustrate the transition from traditional factories to fully digitized and autonomous models, a shift embodied by the Factory 4.0. This evolution relies on technologies such as robotics, the Internet of Things (IoT), and artificial intelligence (AI), enabling the optimization of productivity and flexibility in production processes.

This vision was developed by the Boston Consulting Group, which envisions a future where the integration of these technologies will transform industry, making it more agile, faster, and more efficient, while enhancing the competitiveness of businesses in Île-de-France.

CIM ATLANTIQUE at your service

We support companies in their transition to Industry 4.0 in Île-de-France. Our solutions in robotics, industrial vision, and automation are designed to address the specific challenges of your sector.

Need tailored expertise? Contact us to optimize your industrial processes and accelerate your digital transformation.

Robotics, cobotics, and vision to optimize automation.

By combining IT, robotic automation and machine vision inspection, you can create several high-performanceautomation systems.

Industrial robotics

Industrial robotics now enables the automation of robots to perform all kinds of mechanical tasks. Each case is analyzed, then developed and integrated into its environment.

Industrial vision

Machine vision is the application of computer vision to the industrial fields of production, automation and research.

Cobotics

This approach to automation and technology aims to refine the action of traditional industrial robotics to achieve better cooperation between man and machine.

Speed of execution, network connectivity and quality inspection are the keys toautomation in the factory of the future.

FAQ

Industry 4.0 in Île-de-France

Do you have any questions?

We have the answers.